Instructions for the creation of operating instructions

To avoid accidents and health risks and to protect the environment, the supervisor gives instructions to his or her employees, e.g. in the form of operating instructions. It is advisable, and often required by law, to draw up operating instructions in writing. The advantages of this are

- Systematic summary of the most important aspects of operational safety

- Instructions are simpler, as the most important information is listed in the operating instructions in a short and concise form

- Employees can refer to important safety measures and rules of conduct at any time

- Greater legal certainty for supervisors through compliance with legal requirements

An operating instruction has the status of a binding written order from the employer to the employees. They are therefore also important under labor law.

The legal basis for the creation of operating instructions can be found in § 20 GefStoffV, § 4 ArbSchG and § 9 BetrSichV.

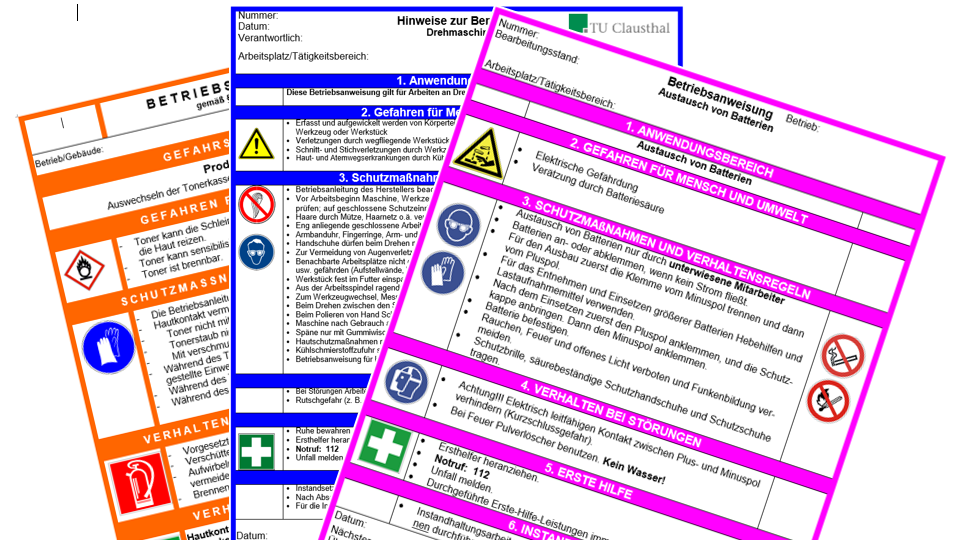

Operating instructions are drawn up according to a predefined practical structure. TRGS 555 specifies the following structure points in an operating instruction:

1. work area, workplace, activity

2. hazardous substances (designation)

3. hazards to humans and the environment

4. protective measures, rules of conduct

5. behavior in case of danger

6. first aid

7. proper disposal

The basic information on the above points can also be found in the manufacturer's safety data sheets.

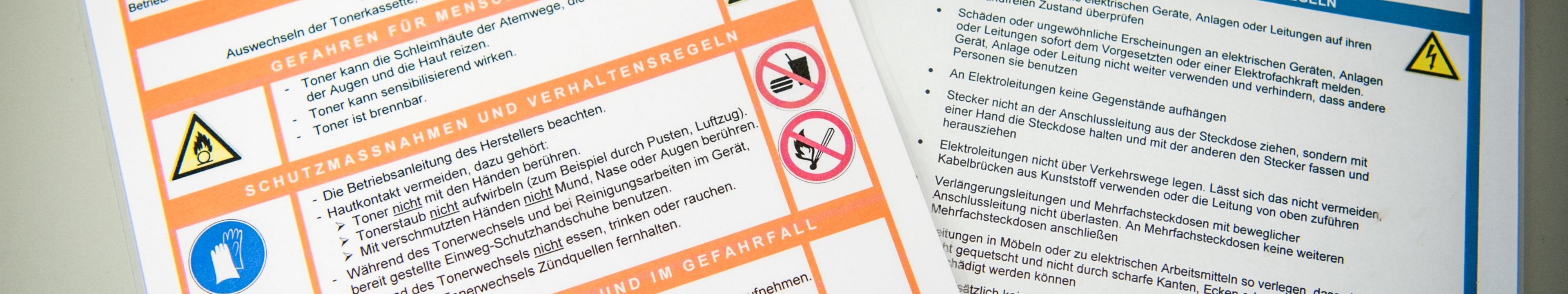

For machines or personal protective equipment etc., the relevant information can be found in the manufacturer's operating instructions and in the rules and regulations of the employers' liability insurance association. The textual content is supplemented by pictograms from the symbol library.

Sample templates can be used for creation.

- For example, the employers' liability insurance associations provide industry-specific sample operating instructions. The main contents have already been worked out, but must be adapted to the operational conditions.

- Some manufacturers also supply operating instructions on request or make them available on their homepage.

You can find a compilation of the most important operating instructions from A-Z on the operating instruction templates page. Please also note the information on handling the operating instruction templates!

- Written form

- comprehensible form and in the language of the employees

- object- and address-related

- should be written in concrete terms

- manageable scope

- graphically uniform presentation

- Use of pictograms

- when handling biological substances

- when handling hazardous substances

- for machines, systems and equipment

- when wearing PPE (personal protective equipment)

- in areas with ionizing or non-ionizing radiation

- for driving and control activities

Sample templates are available for preparation. These must be revised or adapted to the workplace-specific, activity-specific and processing-specific hazards and the conditions of the working environment.

The respective supervisor is responsible for the content.

You can access the templates for operating instructions here.

ImportantThe operating instructions only become binding for the employees once they have been signed by the supervisor.

The completed operating instructions must be discussed with the employees. The easiest way to do this is in the course of documented instruction (template).

The instruction must be carried out annually, or every six months for trainees.

The operating instructions must be displayed/posted in suitable places so that they can be read at any time by the employees working there.

If the working conditions change, the operating instructions must be adapted. It is therefore necessary to check the operating instructions regularly, usually annually.

Contact person

If you have any questions, please contact:

Dipl. Ing. Cyrus Samawatie

Telephone: +49 53 23 / 72-35 35

Mail: cyrus.samawatie@tu-clausthal.de

Flemming Gloyer

Telephone: +49 53 23 / 72-30 22

Mail: flemming.gloyer@tu-clausthal.de